InstallingDeep GrooveBearings

To obtain the simplest attainable performance of the bearings, installation should be performed terriblyrigorously in extremist clean conditions.

Errors throughout fitting of ball bearings will jeopardize the simplest style and make high repair and

maintenance prices. we'd wish to offer some advise for correct mounting of bearings:

The workshop ought to be mud free with low wetness, no compressed gas or machining is allowed.

Only withdraw bearings straight off before installation. If grease is needed it ought to be applied atnow, with a syringe. don't use fingers or a spatula.

The use of a syringe is suggested to inject the grease right between the balls into the ball/raceway空间。几乎所有正常的油脂compati区域单元ble to our rust preventive, thus in most cases it'snot necessary to clean the bearings before greasing. the sole exceptions area unit special greases,supported polymer or halocarbon oils or PTFE-thickeners. They require a clean oil free surface toobtain good adhesion of the grease.

Deep GrooveBearing Mounting

Very few applications entail tight fits on each bearing seats. during this case an impact is mounted

by pressing each rings at the same time. As a result, balls and raceways stay unmarred.

Never clean the bearings in extremist sonic devices! enable the rust preventive to dissolve during慢慢地移动轴承烃浴缸s.

It is counseled to use filtered cleansing hydrocarbon sort 100/140 (max. filter 0.45 microns). Dryingof the bearings ought to happen beneath a dirt cowl. Bearings ought to ne'er be dried by processingwith compressed gas thanks to environmental dirt and moisture!

Finally the bearings, prepared for installation, is mounted by adequate suggests that. it's of utmostimportance to avoid placement of the bearings within the seats which mounting masses ne'er beapplied through the balls.

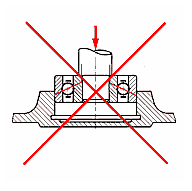

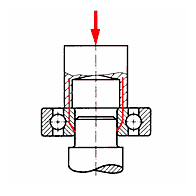

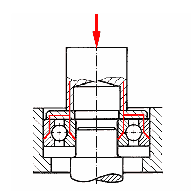

The following footage illustrate the right installation:

The red lines show the road of force whereas pressing the bearings onto their seats. The sketch on the proper shows the mounting forces passing through the balls. This results in indentations within the raceways thence the bearings run shouting and also the service life are reduced.

Deep Groove Bearing Installation

This sketch shows the proper mounting of a control with a decent bore work onto the shaft. Mounting forces ar sentthrough the inner ring solely, balls and races stay free and uninjured.

Deep Groove Bearing Mounting

Very few applications require tight fits on each bearing seats. during this case a control may be mounted by pressing each rings at the same time. As a result, balls and raceways stay uninjured.

Starting Operation

Oil Lubrication

In general, there are not any explicit running-in specifications for oil lubed bearings, however it establishedadvantageous oncelubricant is on the market before start off. take into account length of feed pipes to avoid meagre lubrication,when playacting a brief running-in procedure to permit the bearings to settle in their seats.

Grease Lubrication

Grease lubrication concerns running-in of the bearings. Even once a reduced grease pack is applied to thebearing, a definite quantity of surplus grease causes further friction. an entire grease film should cowl allcontact surfaces.

GMN recommends the subsequent procedure for the bulk of applications:

Starting sequence at ten per cent of operational speed followed by a stop to permit the bearings to chill offto close temperature.

Distribution sequence at fifty per cent of operational speed wherever actual operational temperature slightlyexceeds final operational temperature. once the temperature has reached a most, the unit is stopped to chilloff once more to close temperature. check sequence, 1st operate at nominal speed. If target operationaltemperature is exceeded, the distribution sequence ought to be perennial.

Length and range of sequences depend upon specific properties of the applying. Grease reservoirs, restrictedhouse, operational speed and environmental media have a robust result on the distribution of the grease.

How long and how often this procedure is to be repeated depends on the properties of the application. Tooptimize the running-in process for your specific application, please contact our application engineers. Formore informatin on grease and oil lubrication, review our resource center page.

How to remove and install radial spherical bearings? The following information show you the metho...

The slewing plummer blocks is a large and extra large bearing housing that can accept comprehensi...

Self roller bearings have double row rollers, the outer ring has one shared spherical raceway, an...

According to the different requirements of the bearing and ball bearing units, the classification...

Common equipment using all balls bearings are: motor shafts, transmission parts for light (civil)...

High temperature impact on imperial ball bearings If the lubrication or installation is not appro...

ZYSL factory making ball bearings with customers' customized specifications.Our company has more ...

Radial thrust bearing is divided into thrust ball bearing and thrust roller bearing. Radial thrus...